External blasting machine:

This machine is designed to carry out blasting on external surface of cylindrical surfaces. The component could be a cylinder or a bomb shell having a diameter of 400 /500 mm and length of 1800 mm.

The machine consists of a substantially built blast cabinet with one pair of fixed rolling wheels and a pair of adjustable rolling wheels. The pair of fixed wheels are driven by a geared motor and the pair of adjustable roller wheels can be adjusted to accommodate different length of cylinder or bomb shell. An air operated abrasive recovery system is provided for recirculation of the spent abrasives from the hopper of the blast cabinet to the storage hopper after removal of the fine dust and broken shots. The dust is collected in the dust collector bags keeping the environment clean and green. Once the cycle is completed the blast generator is de-pressurized and the abrasives from the storage tank are fed into the blast generator. The component is placed on the rotating device by opening the pneumatic door assembly of the blast cabinet by the push button provided on control panel. The door is closed before starting the blasting operation to provide safety to the operator. The blasting is started and the blast nozzle is reciprocated horizontally against the diameter of the bomb shell longitudinally to thoroughly blast clean the entire external surface. This longitudinal movement of the nozzle is provided with a variable AC Drive to vary the longitudinal nozzle movement speed and attain the desired level of cleaning. The reciprocation movement is controlled with the help of a limit switch which is set as per the bomb shell length.

The machine is provided with vision glass windows and metal halide lamps for complete look of the component during blasting. The interior of the blast cabinet is lined with wear resistant rubber sheet for long life. The machine is provided with a TC lined convergent divergent blast nozzle of 10 mm ID which gives a cleaning rate of 15 square meters per hour with consumption of 250 cfm of compressed air.

Internal blasting machine:

This machine is designed to carry out blasting on internal surface of cylindrical components. The component could be a cylinder or a Bomb Shell having a diameter of 400 /500 mm and length of 1800 mm.

The components are placed on a swing table on a fixture in vertical position so that the axis of rotation of the table meets with the axis of rotation of the component. This swing table is driven by a geared motor mounted on the external side of the door through a flat belt. The drive to the motor is through a Variable AC drive.

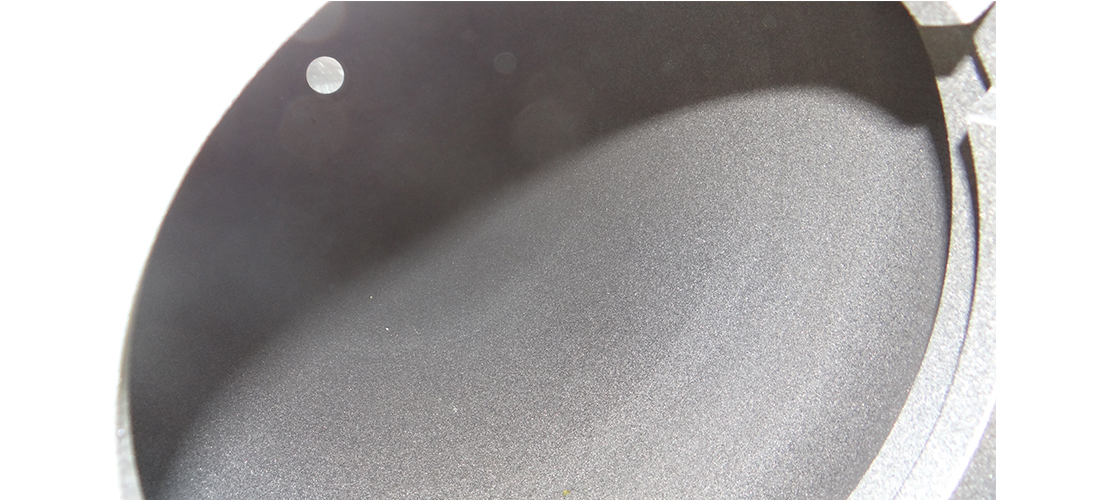

The machine has a substantially built blast cabinet lined with abrasion resistant rubber sheet all around, the area which comes in the direct blast zone is lined with work hardening grade Mn steel sheets to provide long life to the blast cabinet against erosion. The abrasives after internal blasting of the bomb shell gravitates down in the hopper of the machine through the bottom hole of the component and falls into the screw conveyor provided at the bottom of the blast cabinet. The screw conveyor conveys the abrasives in the bucket elevator boot from where the abrasives are picked up by the rubber belt fitted with buckets. These buckets when returns down from the top pulley leaves the abrasive in the separator of the machine which separates out the broken abrasives from the usable abrasives by means of air currents drawn through the falling abrasives in the form of a curtain thereby separating the usable abrasive media from the fine and non-usable abrasive media. The usable media is stored into the storage hopper whereas the broken abrasives are rejected from the system through a refuse pipe.

The abrasive media slides into the blast generator from the storage hopper once the blast generator is depressurized. The blast generator is made and tested as per pressure vessel norms and is of twelve cubic feet capacity and can accommodate 1.2 tons of abrasive media at a time. A dump valve is provided on the top side of the blast generator which isolates and seals the blast generator from the storage hopper no sooner the solenoid valve of the dump valve is actuated and the high pressure air is allowed to enter the dump valve. The high pressure air is then permitted to enter the blast generator pressurizing the abrasive media in it. The bottom side of the blast generator is fitted with two Thomson valve which permit regulated abrasive flow from the blast generator to the blast hose from where this abrasive is carried away to the blast nozzle at high velocity by the compressed air.

Especially designed two number angular CD Tungsten Carbide nozzles with +/- 40 degree angle are provided to achieve perfect cleaning and roughness in the cylindrical area as well as the lower and top curved contures. The two nozzles are connected with the Thomson valves by means of abrasive resistant grit blasting hose pipes. Reciprocating arrangement for these two nozzles is provided in the vertical plane by means of a servo drive which is programmed to reciprocate with in the preset limits once the bomb shell/ cylinder is selected on the HMI. The reciprocation stroke is 2000 mm. The reciprocation is so programmed that the non-blasting strokes are covered at 15 times the speed defined for blasting operation to save unproductive time.

The machine is provided with a high efficiency cartridge type dust collector with emission levels below 5 microns particle size. This dust collector sucks the dust from the blast cabinet during blasting operation and also support in effectively separating the usable and non-usable abrasives at the separator thus keeping the environment clean and healthy.

The machine is provided with IP-54 protection Rittal make control Panel fitted with S-200 series Siemens PLC and colored touch screen HMI. The program is menu selection type. The operator has to select the size of the bomb shell or cylinder. All parameters get automatically selected by the PLC and the machine runs as per the sequence of operation and time fed during programming. The machine is designed with all safety norms in mind. Blasting will not start unless the door is closed. The door will get locked no-sooner the cycle starts. This also prevents from un-locking of the door unless the cycle is completed. The machine is able to achieve Ra values from 11 to 16 microns depending upon the hardness of the bomb shell cylinder.